Supreme Mannings - Our Services - Frequency Testing of Blades

NATURAL FREQUENCY TESTING OF THE FREE STANDING BLADES OF THE LP TURBINE ROTOR

When an object is hit or struck or plucked or strummed or somehow disturbed, will vibrate. If we drop a meter stick or pencil on the floor, it will begin to vibrate.

If we pluck a guitar string, it will begin to vibrate. If we blow over the top of a pop bottle, the air inside will vibrate. When each of these objects vibrates,

they tend to vibrate at a particular frequency or a set of frequencies. The frequency or frequencies at which an object tends to vibrate with when hit, struck,

plucked, strummed or somehow disturbed is known as the natural frequency of the object. Concentration of excessive vibration energy can lead to excessive

vibrational amplitudes. This leads the vibrating object to failure due to fatigue. In a turbine the components most prone to failure by this mechanism are

the rotor blades. Among the various turbine stages, the blades associated with the low pressure stages-especially the blades with large length at the last

couple of stages of the LP rotor are most prone to excessive vibrations excited by various disturbing forces encountered in a turbine. These blades are

designed in such a way that their natural frequencies are away from the prevailing excitation frequencies. If the natural frequencies of these blades be

same or very close to the excitation frequencies then a resonance is formed and the blades tend to vibrate with larger vibrations and fail.

A rotating body, like the turbine blades posses a natural frequency of motion at which it offers minimum resistance to cyclic excitation of forces. We must check the natural

frequencies of the Turbine blades so that the values of the natural frequencies are away from the excitation frequencies. The natural frequency is dependent

on the mass of the component and the stiffness it offers to the external forces. For the free standing turbine blades the rigidity is offered by the root

contact of the blades with the groove. When the turbine rotates at a speed of 3000rpm due to the centrifugal forces the free standing blades tend to

move outwards and the blades move upwards in the grooves. To excite this condition on a stationary rotor we normally fix a wedge type object which we

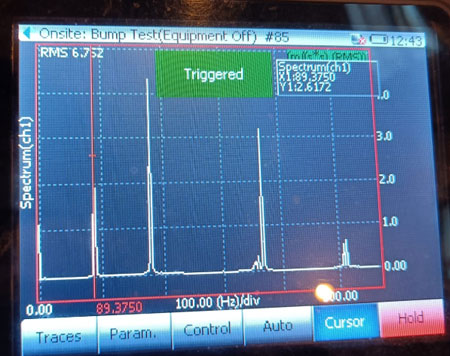

call "Technological Pieces" at the slot of the root of the blades on the disc. The technique used to determine the natural frequencies of the blades

involves exciting the blades by hammering with an instrument tuned specially made hammer, which does not give bouncing effect, and the resulting vibrations

are picked by an accelerometer, are recorded in FFT Analyzer and stored.